Delving into the realm of the latest smart robotics in manufacturing opens up a world of innovation and efficiency. As technology continues to advance, these intelligent machines are reshaping the landscape of production processes, offering a glimpse into the future of manufacturing.

From enhancing precision to optimizing efficiency, smart robotics have become indispensable in modern manufacturing, revolutionizing the way products are made and delivered to consumers.

Overview of Smart Robotics in Manufacturing

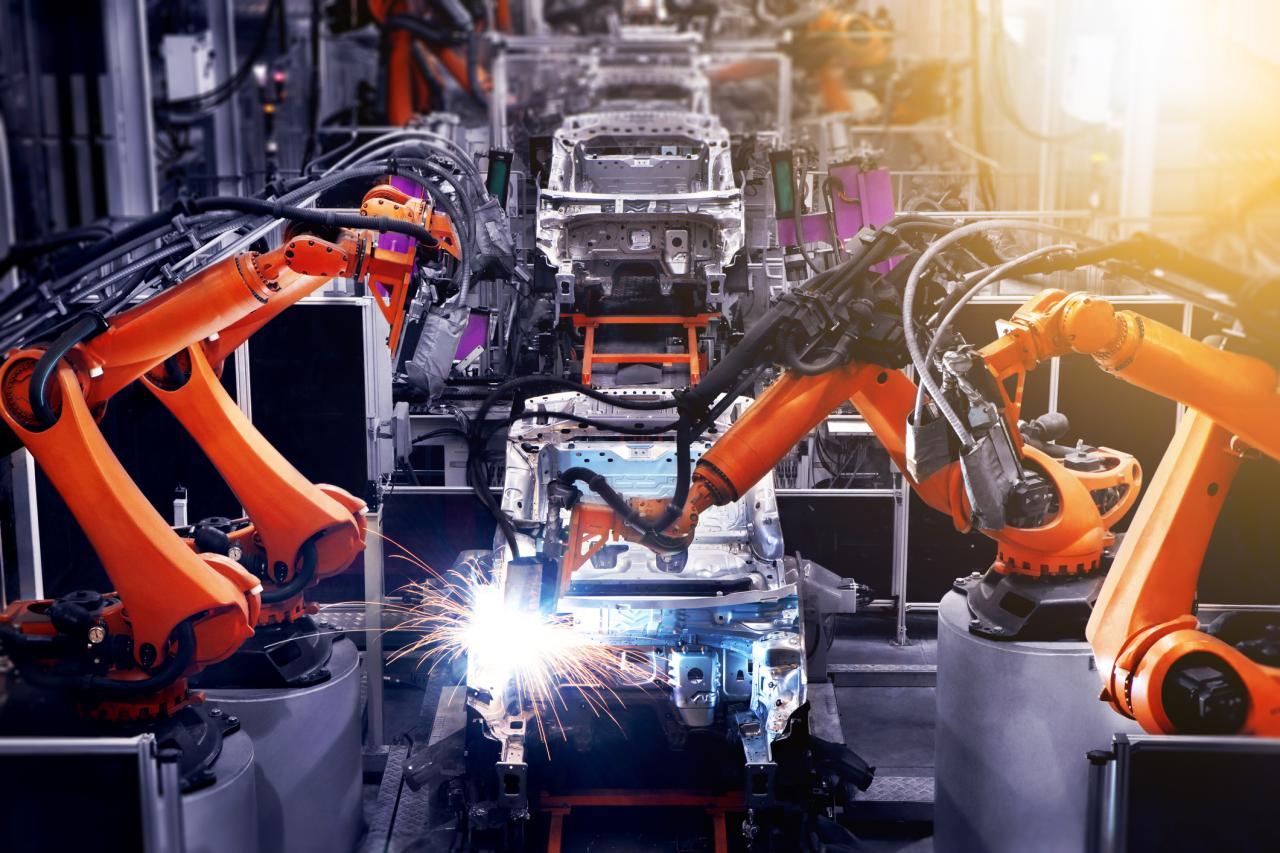

Smart robotics in manufacturing refers to the use of advanced robotic systems equipped with artificial intelligence and automation technology to optimize and improve various processes within the manufacturing industry. These robots are designed to perform tasks with precision, efficiency, and consistency, ultimately enhancing productivity and reducing operational costs.The importance of smart robotics in manufacturing cannot be overstated.

By incorporating these intelligent machines into production lines, manufacturers can significantly streamline their operations, increase output, improve product quality, and enhance workplace safety. Smart robotics also offer the flexibility to adapt to changing production demands quickly, making them invaluable assets for modern manufacturing facilities.

Revolutionizing Manufacturing Processes

- Automating Repetitive Tasks: Smart robotics are capable of handling repetitive tasks with high accuracy and speed, freeing up human workers for more complex and creative assignments.

- Enhancing Quality Control: Advanced sensors and AI algorithms enable robotic systems to detect defects and deviations in real-time, ensuring consistent product quality.

- Increasing Efficiency: By optimizing production workflows and minimizing downtime, smart robotics help manufacturers achieve higher levels of efficiency and output.

- Enabling 24/7 Operations: Robotic systems can operate round-the-clock without the need for breaks, leading to continuous production and faster turnaround times.

Applications of Smart Robotics in Manufacturing

Smart robotics have revolutionized the manufacturing industry by increasing efficiency, precision, and productivity. Let's delve into how these advanced technologies are utilized in various aspects of manufacturing processes.

Assembly Lines

Smart robotics play a crucial role in assembly lines by automating repetitive tasks and speeding up production processes. These robots can handle intricate tasks with precision, such as welding, screwing, and painting, ensuring consistent quality and reducing the risk of human errors.

Quality Control Processes

Smart robotics are used in quality control processes to inspect products for defects, anomalies, or deviations from set standards. These robots can conduct thorough inspections at a faster pace than manual labor, ensuring that only high-quality products reach the market.

They utilize advanced sensors and cameras to detect even the smallest imperfections.

Material Handling and Packaging

Smart robotics are employed in material handling and packaging to streamline logistics operations and improve overall efficiency. These robots can transport heavy materials with ease, sort and organize items in warehouses, and package products accurately and swiftly. By automating these tasks, manufacturers can optimize their supply chain and reduce operational costs.

Advantages of Implementing Smart Robotics

Implementing smart robotics in manufacturing comes with a multitude of benefits that significantly impact efficiency, accuracy, and cost-effectiveness.

Increased Efficiency through Smart Robotics

Smart robotics streamline manufacturing processes by performing repetitive tasks with speed and precision, leading to a significant increase in overall efficiency. These robots can work around the clock without fatigue, resulting in higher productivity levels.

Improved Accuracy and Precision

Smart robotics are equipped with advanced sensors and technology that enable them to perform tasks with unparalleled accuracy and precision. This ensures consistent quality in manufacturing processes, reducing errors and rework.

Reduced Operational Costs

By implementing smart robotics, manufacturers can reduce operational costs significantly

Challenges and Limitations of Smart Robotics in Manufacturing

Integrating smart robotics into manufacturing processes comes with its own set of challenges and limitations that companies need to address in order to fully leverage the benefits of this technology.

1. Programming Complexity

One of the main challenges of smart robotics in manufacturing is the complexity of programming these machines. Traditional robots are often programmed for specific tasks, but smart robots need to be adaptable and learn new tasks on the go, which requires advanced programming skills and algorithms.

2. Cost of Implementation

Another limitation is the high initial cost of implementing smart robotics in manufacturing facilities. Companies need to invest in not only the robots themselves but also in training employees to work alongside these robots and maintain them.

3. Lack of Flexibility

While smart robotics offer increased efficiency and precision, they may lack the flexibility to handle unexpected changes in the manufacturing process. This can limit their adaptability in dynamic production environments.

4. Data Security Concerns

With the increase in connectivity and data exchange in smart robotics, there is a growing concern about data security. Companies need to ensure that sensitive information and intellectual property are protected from cyber threats and breaches.

5. Maintenance and Downtime

Smart robotics require regular maintenance to ensure optimal performance, and any downtime can lead to disruptions in production schedules. Companies need to have contingency plans in place to minimize the impact of maintenance and repairs.

Ending Remarks

In conclusion, the latest smart robotics in manufacturing represent a pivotal shift in how industries operate, promising increased productivity, quality, and cost-effectiveness. Embracing these advancements is key to staying competitive in a rapidly evolving market.

Key Questions Answered

What are the key benefits of smart robotics in manufacturing?

Smart robotics enhance efficiency, accuracy, and precision, leading to improved productivity and reduced operational costs.

What challenges are faced when integrating smart robotics into manufacturing processes?

Challenges may include initial high costs, training employees to work alongside robots, and potential technical glitches during implementation.

How do smart robotics impact quality control processes in manufacturing?

Smart robotics ensure consistent quality by performing precise inspections and identifying defects in real-time, improving overall product quality.