In today's fast-paced world, smart factory automation solutions have revolutionized the way industries operate. From streamlining processes to enhancing productivity, these solutions offer a glimpse into the future of manufacturing. Let's delve deeper into the realm of smart factory automation and discover the endless possibilities it holds.

Smart factory automation solutions are paving the way for a more efficient and optimized manufacturing landscape. With cutting-edge technologies at the forefront, businesses are embracing automation to stay ahead of the curve and drive success.

Overview of Smart Factory Automation Solutions

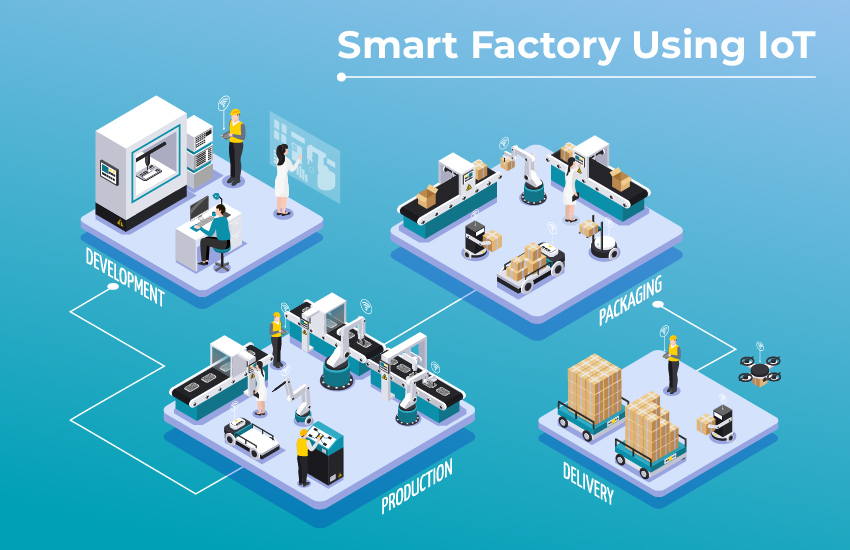

Smart factory automation solutions refer to the integration of advanced technologies like artificial intelligence, machine learning, robotics, and IoT to streamline and optimize industrial processes. These solutions aim to enhance efficiency, productivity, and flexibility in manufacturing operations.Industries such as automotive, electronics, food and beverage, pharmaceuticals, and aerospace are among those benefiting greatly from smart factory automation solutions.

These technologies help in reducing operational costs, minimizing errors, improving quality control, and enabling real-time monitoring and decision-making.

Primary Goals of Implementing Smart Factory Automation Solutions

- Increased productivity: By automating repetitive tasks, smart factory solutions can boost production output and efficiency.

- Enhanced quality control: Automation helps in maintaining consistent product quality and reducing defects.

- Cost reduction: By optimizing processes and reducing manual labor, companies can lower operational costs.

- Real-time monitoring and analytics: Smart factory solutions provide valuable data insights for informed decision-making and predictive maintenance.

- Improved safety: Automation can handle hazardous tasks, ensuring a safer working environment for employees.

Technologies Driving Smart Factory Automation

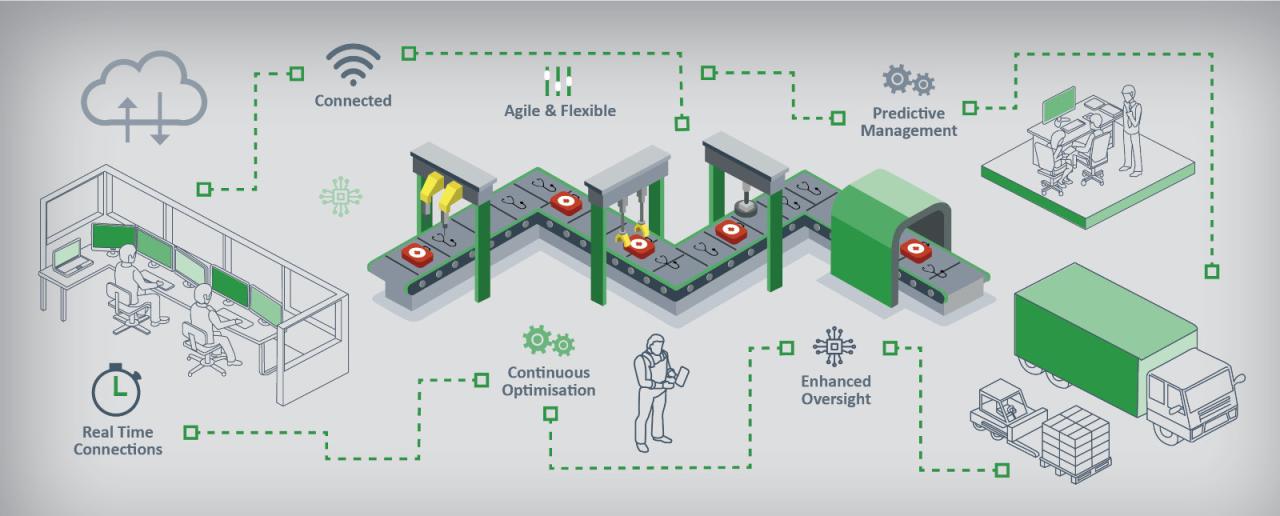

Automation in smart factories is powered by a combination of cutting-edge technologies that work together to streamline processes, improve efficiency, and enhance productivity. Key technologies driving smart factory automation include the Internet of Things (IoT), Artificial Intelligence (AI), and machine learning.

Internet of Things (IoT)

The IoT plays a crucial role in enabling automation in factories by connecting various devices, sensors, and machines to collect and exchange data in real-time. This interconnected network allows for seamless communication and data transfer, enabling smart decision-making and control of manufacturing processes.

By leveraging IoT technology, smart factories can optimize operations, monitor equipment performance, and predict maintenance needs, ultimately leading to increased productivity and reduced downtime.

Artificial Intelligence (AI) and Machine Learning

AI and machine learning are instrumental in smart factory automation, providing the ability to analyze vast amounts of data, identify patterns, and make autonomous decisions. These technologies enable predictive maintenance, quality control, and process optimization by continuously learning from data and adapting to changing conditions.

By utilizing AI and machine learning algorithms, smart factories can enhance efficiency, minimize errors, and drive innovation in manufacturing processes.

Benefits of Implementing Smart Factory Automation

Implementing smart factory automation solutions can bring numerous benefits to businesses, revolutionizing the way manufacturing processes are carried out. Automation not only enhances efficiency and productivity but also plays a crucial role in maintaining high-quality standards and reducing costs.

Enhanced Efficiency and Productivity

- Automation streamlines repetitive tasks, reducing the time required to complete them and allowing employees to focus on more complex and strategic activities.

- By optimizing workflows and eliminating manual errors, smart factory automation ensures a smoother production process, leading to increased output and faster turnaround times.

- Real-time monitoring and data analysis provided by automation systems enable quick decision-making and proactive adjustments, further enhancing overall efficiency.

Improved Quality Control

- Automation systems can consistently perform tasks with precision, reducing variability in products and ensuring a high level of quality across the production line.

- By incorporating sensors and monitoring devices, smart factory automation can detect defects or deviations early in the process, minimizing the chances of faulty products reaching customers.

- Automated quality control processes lead to higher customer satisfaction, increased brand reputation, and reduced rework or warranty costs.

Cost Savings and Waste Reduction

- Automation helps in reducing labor costs associated with manual tasks, as well as minimizing the risk of human errors that can lead to costly mistakes or rework.

- Efficient use of resources, optimized production schedules, and reduced downtime result in lower operational costs and increased profitability for businesses.

- By improving inventory management and minimizing waste through precise control of materials, smart factory automation contributes to sustainable practices and environmental benefits.

Challenges Faced in Adopting Smart Factory Automation

Implementing smart factory automation solutions comes with its own set of challenges that companies need to address. From legacy system integration to cybersecurity concerns, there are several obstacles to overcome in the adoption of automation technologies.

Legacy System Integration

When upgrading to smart factory automation, one of the key challenges is integrating these new technologies with existing legacy systems. Legacy systems may not be designed to communicate with modern automation solutions, leading to compatibility issues and potential disruptions in production processes.

Companies need to invest time and resources into ensuring a smooth transition and seamless integration to avoid any downtime or inefficiencies

Cybersecurity Concerns

As smart factory automation relies heavily on interconnected devices and networks, cybersecurity becomes a major concern. The more devices connected, the higher the risk of cyber threats and attacks. Companies need to implement robust cybersecurity measures to protect sensitive data, intellectual property, and production processes from potential breaches.

This includes implementing firewalls, encryption, access controls, and regular security audits to ensure the integrity of the automation systems.

Implementation Strategies for Smart Factory Automation

Implementing smart factory automation requires careful planning and execution to ensure a successful transition. One of the key aspects of this process is the implementation strategies that guide the adoption of automation technologies in manufacturing facilities.

Employee Training and Change Management

Employee training and change management are crucial components of implementing smart factory automation. It is essential to provide employees with the necessary skills and knowledge to operate and maintain automated systems effectively. Additionally, change management strategies help employees adapt to the new technologies and processes, minimizing resistance to change.

Successful Automation Implementation Strategies

- Develop a comprehensive implementation plan: Creating a detailed roadmap outlining the steps involved in the automation process helps in setting clear goals and timelines.

- Collaborate with automation experts: Working closely with automation solution providers can help in selecting the right technologies and implementing them effectively.

- Start small and scale gradually: Beginning with pilot projects allows for testing and refinement before full-scale implementation, reducing risks and costs.

- Monitor and evaluate performance: Regularly assessing the impact of automation on productivity, efficiency, and quality helps in identifying areas for improvement and optimization.

Case Studies of Smart Factory Automation Success Stories

Automation has revolutionized the manufacturing industry, leading to increased efficiency, reduced costs, and improved quality. Let's explore some case studies of companies that have successfully implemented smart factory automation solutions.

Company A: Streamlining Production Processes

- Company A, a leading automotive manufacturer, implemented smart factory automation to streamline their production processes.

- By integrating robotic arms and IoT devices, they were able to automate repetitive tasks and improve production speed.

- This led to a significant increase in productivity, reduced errors, and minimized downtime.

Company B: Enhancing Quality Control

- Company B, a pharmaceutical company, adopted smart factory automation to enhance their quality control processes.

- Through the use of AI-powered systems and sensors, they were able to monitor production lines in real-time and detect any deviations from set standards.

- As a result, they improved product quality, reduced waste, and ensured compliance with regulatory requirements.

Company C: Optimizing Supply Chain Management

- Company C, a consumer goods manufacturer, leveraged smart factory automation to optimize their supply chain management.

- By implementing automated inventory tracking systems and predictive analytics, they were able to streamline logistics operations and reduce lead times.

- This led to cost savings, improved inventory management, and enhanced customer satisfaction.

Last Point

As we wrap up our exploration of smart factory automation solutions, it becomes clear that the future of manufacturing is indeed smart. By leveraging automation, businesses can unlock new levels of efficiency, productivity, and profitability. Embracing these innovative solutions is not just a choice but a necessity in today's competitive market.

General Inquiries

What are some industries benefiting the most from smart factory automation solutions?

Industries such as automotive, electronics, pharmaceuticals, and food processing are among those reaping the benefits of smart factory automation solutions due to their complex manufacturing processes and high demand for quality control.

How do smart factory automation solutions contribute to cost savings?

By automating repetitive tasks, optimizing resource utilization, and minimizing errors, smart factory automation solutions lead to reduced operational costs, increased efficiency, and improved overall profitability for businesses.

What are some common challenges faced in adopting smart factory automation?

Common challenges include the high initial investment costs, resistance to change from employees, integration issues with existing systems, and ensuring cybersecurity measures are robust to protect automated processes from threats.